Why ewifoam®?

- Expert in the field of insulating underlays

- The widest range of insulating underlays

- Suitable underlays for every kind of floor and every area of application

- Modern and safe logistics adapted to individual customer needs

- Quality confirmed by numerous certificates and awards

- Individual sales promotion

SELECTED PRODUCTS

Impact sound insulation – an important detail

European specialist for professional acoustic insulation underlays

It is worth choosing insulation underlays from proven European manufacturers such as Ewifoam. Ewifoam is a recognized European manufactured brand of underlays that meet the highest quality standards. We are a subsidiary of the listed stock market company Decora S.A., which operates worldwide and is consistently striving to become the market leader. We are the only company in Europe to use three unique technologies to manufacture floor underlays.

Right underlay for your floor

There are different types of floor coverings on the market: wooden parquet - still popular, laminate floors and modern vinyl floors. Each of these materials requires a different underlayment, which emphasizes all its advantages and eliminates disadvantages. The purpose of a well-fitted underlay is to protect the floor from damage while improving its performance. Whether for laminated planks, wood or vinyl planks, Ewifoam offers the right solutions. We produce underlays for the three floor types in three technologies.

Underlay for underfloor heating system - a challenge for the best

Underfloor heating installation is a modern and practical solution for house heating. However, it usually means higher costs and a technological challenge. If we want to decide on underfloor heating, it is worth doing it as effectively as possible. Only the best underlay guarantees the comfort of underfloor heating. A well-adapted underlay guarantees safe and effective use and the longevity of your floor covering, even over underfloor heating, so there is no need to skimp when choosing the right insulating underlay. Ewifoam insulation underlays for underfloor heating are characterized by a very low thermal resistance, which means that you can save a lot on heating costs.

Choosing an insulation underlay for vinyl floors

Vinyl planks are relatively thin and have precisely milled click connections, so special underlays are required here, which ensure acoustic comfort, increase the efficiency of underfloor heating and can effectively protect the click connections of the planks. A very good choice for vinyl flooring is PUM (polyurethane + mineral) underlays. They can also be used with underfloor heating (e.g. Ewifoam Vinclic Professional) and thanks to their very low thermal resistance coefficient they help to realistically reduce heating costs and heating time in the house or apartment. Choose special insulating underlays for design floors - they are usually marked with LVT. Ewifoam withstands all technological challenges and offers different kinds and types of underlays for vinyl floors, like the underlay mentioned above, but also clever 3-in-1 underlays with click system (underlay + film + adhesive tape in one product).

A good acoustic insulation underlay ensures a quiet, safe and effectively used floor covering. Their quality therefore depends on whether our floorboards will maintain the parameters specified by the manufacturer over a long period of time. And perhaps more importantly, the installation of a proper underlay is a prerequisite for any warranty claims for the entire floor.

When choosing the right underlay, we first determine whether we need a product for laminate or vinyl floor. Since the latter are relatively thin and have precisely milled click joints, it is advisable to lay a special underlay that provides acoustic comfort, increases the efficiency of underfloor heating and effectively protects the click joints of vinyl planks. In the case of ordinary laminate floorboards, which are noisier due to their manufacturing technology and create higher resistance to underfloor heating, a well-adapted underlay is the absolute basis for acoustic comfort and improving energy efficiency.

What should be considered when choosing the right acoustic insulation underlay? :

- the subfloor type

- light or intensive use

- Walking / impact sound insulation

- Underfloor heating (energy class)

- Cold insulation (e.g. in the space above the garage)

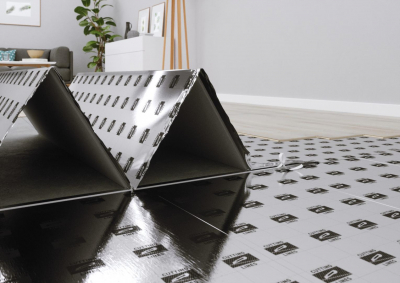

Simplicity and time of laying play an important role in the choice of product. The quickest way is to use PUM underlays because they are offered in rolls and are simply unrolled like a carpet during installation. The folding board, so-called SMART, is becoming more and more popular, which reduces the laying time by five times compared to board underlays. Integrated 3-in-1 underlays are also available on the market: the product includes insulating underlay, vapor barrier film and adhesive tape. Of course, the choice depends on our needs.

With underfloor heating, we should reach for a special insulating underlay. PUM underlays (polyurethane + minerals) are ideal for underfloor heating; the best heavy mats have a thermal resistance of R-0.006 m2 K/W.

Note that the properties of a good acoustic insulation underlay guarantee not only the longevity of our floor, but also thermal and acoustic comfort in the room.

Anyone who has laminate flooring at home knows the problem of noise when using it. You can either hear walking noise – in the same room, or impact noise – in other rooms, e.g. one floor below. Unfortunately, it is not possible to completely eliminate the noise, but the use of a suitable acoustic insulation underlay reduces it considerably. The reduction is specified by the manufacturers of the floor underlays in % for walking noise (RWS - Reflected Walking Sound) and in decibels for footsteps (IS - Impact Sound). The higher the value, the better the soundproofing.

With the best floor underlays available on the market, the RWS value is almost 30% and the IS is around 20 dB. The noise reduction is measured using specially developed test methods (e.g. EN 16205 CEN / TS 16354 for RWS). Manufacturers of professional acoustic insulation underlays base their research on the guidelines of the European Association of Laminate Flooring Manufacturers (EPLF).

When choosing the insulating underlay, it is advisable to opt for a product dedicated to a specific type of floor. The Ewifoam brand offers a wide range of special acoustic insulation underlays. The Ewifoam Vinclic Standard is the best choice for Ewifoam design floors and the Ewifoam UNIVERSOL Akustik Alu 3in1 for laminate floors. Thanks to the high compressive strength (CS value), both products increase the resistance and durability of the planks, protect the sensitive click connections and extend the life of the floor covering. In addition, they reduce noise in the room by up to 18 dB. With the combination of vinyl planks with the HD mineral core and the EWIFOAM Vinclic Classic Smart N, we get one of the quiet floor.

Which acoustic insulation underlay for quiet rooms?

- Polyurethane + minerals (PUM – underlays): low thickness and a very effective sound insulation for both walking and impact noise. In addition, there is good heat transmission, which is important with underfloor heating. A product worth its price.

- Underlays made of extruded polystyrene (XPS): very good impact noise reduction, the RWS value for walking noise is 10 - 14%, which at least minimizes the noise. An additional advantage: they are relatively inexpensive.

- Underlays made of high-density polyethylene (PEHD): very good noise reduction of both types with low thickness of the mats. A good and inexpensive solution.

When we buy a new floor, we expect it to serve us for many years. The manufacturers even give us a guarantee of up to 25 years on their products and we rarely check their conditions in advance. And every guarantee has its limitations. When it comes to floor coverings, the underlay often plays an important role.

In order to be able to use our new floor safely and comfortably, we should familiarize ourselves with the manufacturer's instructions and strictly follow them. They usually contain three important aspects:

- Properly prepared subfloor : The floor covering should be laid on a stable and level sub-floor, the deviation of which must not exceed 2 mm per 200 cm. The subfloor for laminate floors must be dry, clean and stable. Since laminate planks are very sensitive to moisture, it is worth checking the moisture content with a CM meter. The moisture content of the concrete substrate must not exceed 2% CM and that of anhydrite screed 0.5% CM. With underfloor heating installed, the above values must not exceed 1.8% CM and 0.3% CM respectively.

- Appropriate room humidity : The humidity in the room can also increase the humidity of the substrate. Before laying the floor covering, make sure the room temperature is adequate (+18 to 23 degrees) and control the relative humidity (50-70%) in the room. Investments nowadays are usually made under great time pressure, so an accurate measurement of humidity is extremely important. A damp substrate plus walls that have not yet dried are an absolute contraindication for laying a new floor.

- Proper moisture protection : Before you lay your floor covering on a mineral substrate, think about a moisture barrier that protects the floor from residual moisture in the substrate. If underfloor heating is installed, a vapor barrier is also necessary. This layer serves as a permanent protection against soil moisture. We can choose a vapor barrier film or an underlay with built-in moisture insulation. When choosing the first solution, we should not be guided by the thickness of the film, but by the SD coefficient - the higher the value, the better the floor is protected from moisture. The minimum required value is SD > 75 m. A faster and more reliable alternative is to use 2-in-1 underlays with an integrated vapor barrier film or 3-in-1 underlays, which also include an adhesive tape that connects individual sheets relieved. All of the above product types can be found in the Ewifoam range. Not only are they of excellent quality, but they are also easy to use.

A precisely selected and laid underlay extends the life of our floor. It protects the click connections from mechanical damage, increases the comfort of use and reduces the noise generated when using the floor covering.

Please note that an underlay is not used to level unevenness on the subfloor - this is particularly important in the event of any complaints. Before laying, the subfloor must be level and clean; the underlay can only compensate for small, isolated unevenness.

When buying a floor underlay, pay attention to the CS value. This parameter determines how resistant our underlay is to loads. Its value is expressed in kPa: the higher the CS coefficient, the better the underlay behaves to heavy loads, which protects the delicate click joints of the flooring from damage and does not transmit vibrations to the planks.

A good insulation underlay is just as important as the material from which it is made. This - although invisible - must not be underestimated. Thanks to a good floor underlay, we can not only enjoy a beautiful floor covering in a quiet room for many years, but also really reduce heating costs. Ewifoam offers underlays for different floor types in different premises, for homes with and without underfloor heating. They are manufactured using different technologies and are used in different ways depending on the needs. The most important thing is the right choice.